Positive Displacement Blowers

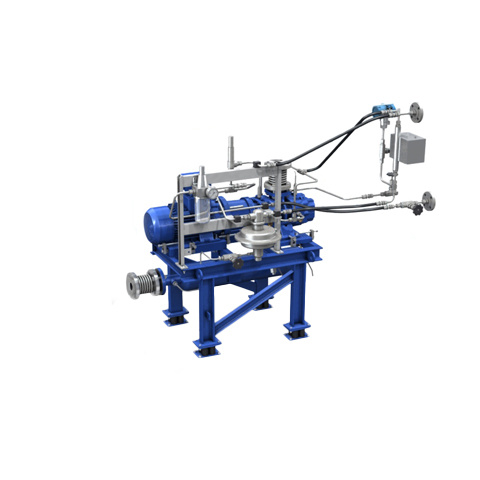

Low Pressure Gas Booster

Series GMD

The GMD series, made by AERZEN, is the universal gastight booster solution for the low pressure range. Equipped with a magnetic coupling, it ensures a maintenance-free sealing concept. Locking systems for sealing the drive shaft are completely eliminated and allow a low-maintenance machine concept. The separation between oil and process side is achieved by a special piston ring seal.

Volume flow:

30

to

11.000

m3/h

Differential pressure (Δp):

150

to

1.000

mbar

Medium:

Process Gases

Conveying:

Oil-free

Process gas blowers from AERZEN work reliably in all industries and in all markets and countries of the world.

AERZEN offers the process gas and refrigeration industry an enormously wide range of blower technologies - perhaps the widest ever. The machines work in a stand-alone manner, in a machine or container combination, onshore and offshore. You find them in really all key industrial applications.

Industrial gases

- Air separation

Oil & gas extraction and storage

- Gas recovery (VRU)

- Decarbonisation/tertiary oil recovery

Chemical industry

- Acetylene circular gas

Petrichemistry, refineries

- Ethylene, propylene, olefin (feed gas compression)

- Butadiene (extractive distillation)

Industrial research & development

- Circular processes (inert gases, purge gases)

Glass industry

- Oxygen injection (melting furnace)

- Tin bath protective atmospheres (hydrogen, nitrogen)

US Units

No- Type of technology

- Positive Displacement Blowers

- Differential pressure (Δp)

- 150 to 1.000 mbar

- Volume flow

- 30 to 11.000 m3/h

- Medium

- Process Gases

- Conveying

- Oil-free

Gas boosters for low pressure applications

The GMD series from AERZEN is the universal gastight booster solution for the low-pressure range. Equipped with a magnetic coupling, it guarantees a virtually maintenance-free sealing concept. Locking systems for sealing the drive shaft are completely eliminated and allow a low-maintenance machine concept. The separation between oil and process side is achieved by a special piston ring seal. The robust two-lobe design allows a design pressure of 7.0 barg according to AD2000/DIN EN 13445. 16 sizes guarantee optimum efficiency and operation conditions for every design case.

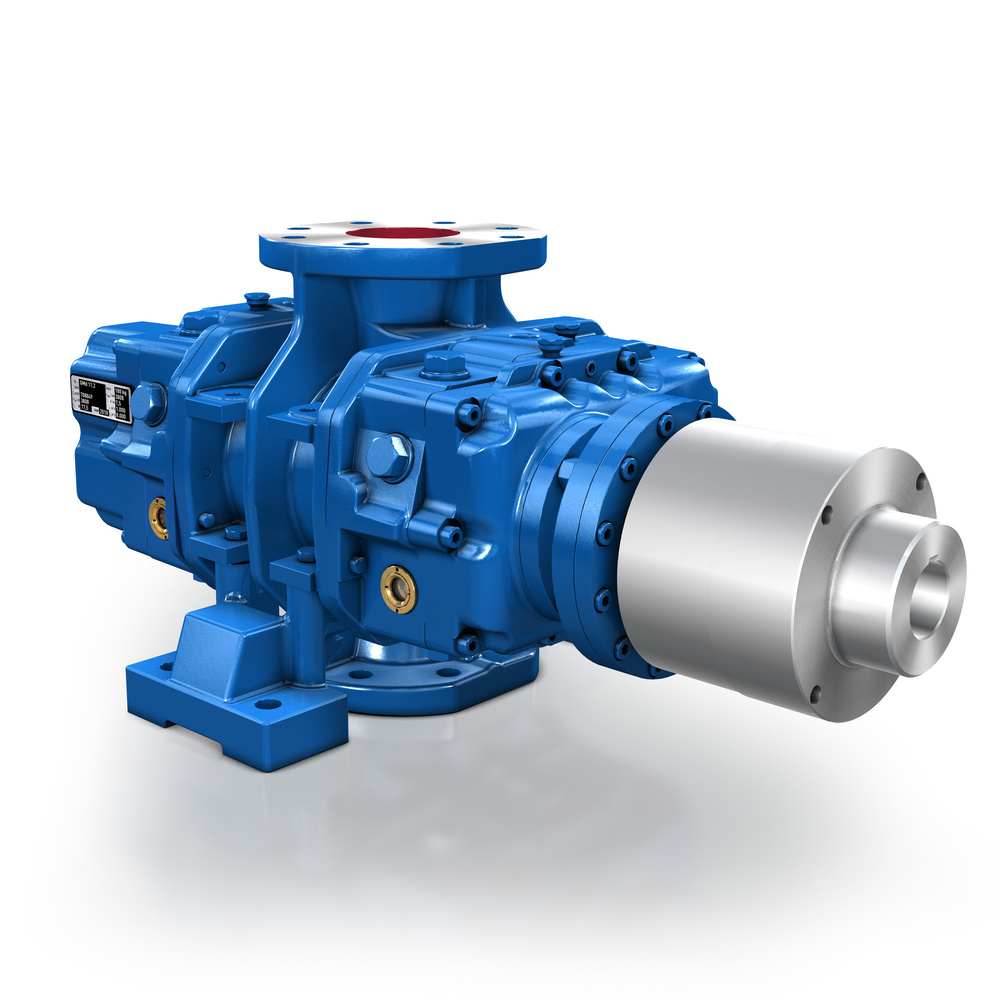

Design:

Nodular iron or stainless steel housing with round flanges and O-ring seals.

Sealings:

Shaft sealing by hermetically sealed magnetic coupling. Alternatively oil-purged double-acting mechanical seal with thermosiphon cooling for torques ≥ 600 Nm.

Direction of flow:

Vertically downwards.

Drive:

Direct coupling with motor (type of construction B35 for magnetic coupling or B3 for alternative shaft sealing via mechanical seal).

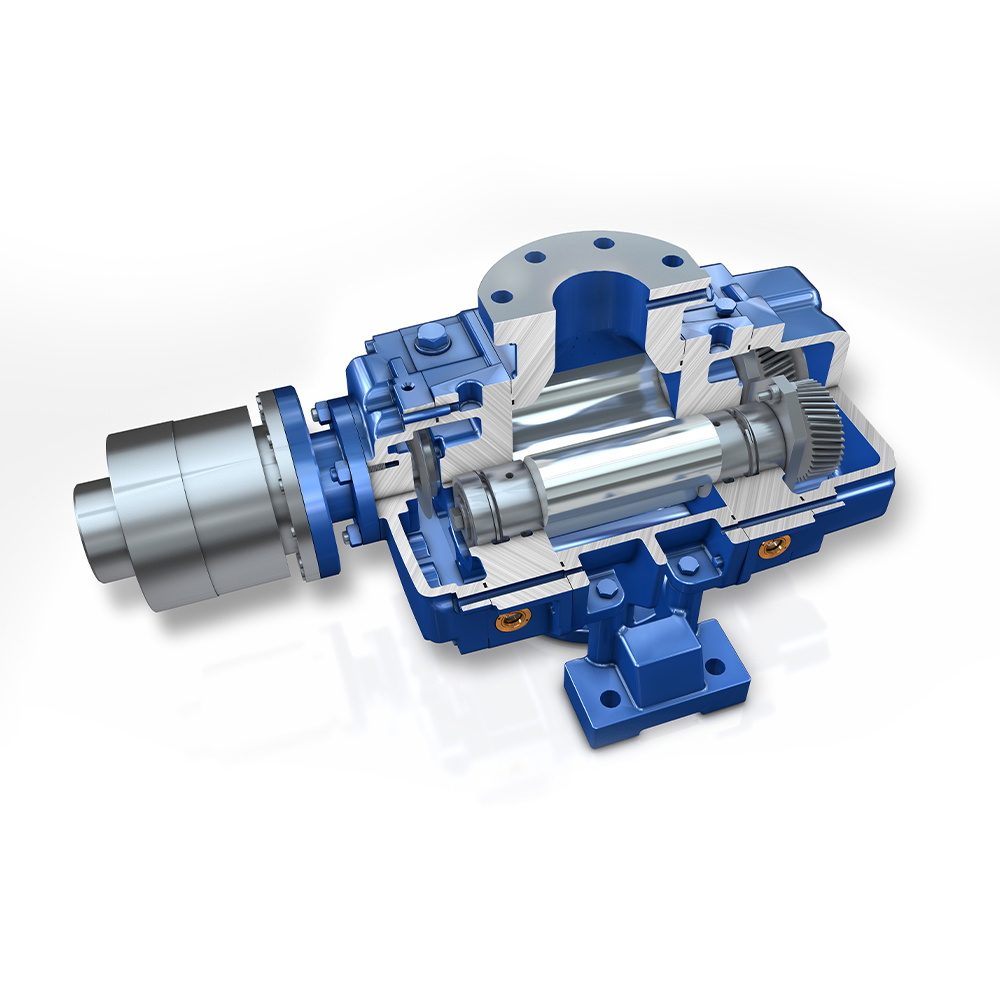

Design:

- Max. pressure increases of 1.0 bar

- Splash lubrication

- Separation of the oil chambers and the conveying chamber by grey cast iron or PEEK piston seals

- Separation of conveying and oil chamber possible through separating gas

- Sealing of drive shaft by hermetically sealed magnetic coupling, optionally by oil-lubricated double-acting mechanical seal

- Maximum pressure 7.0 bar (g)

- Housing sealed with O-ring seals