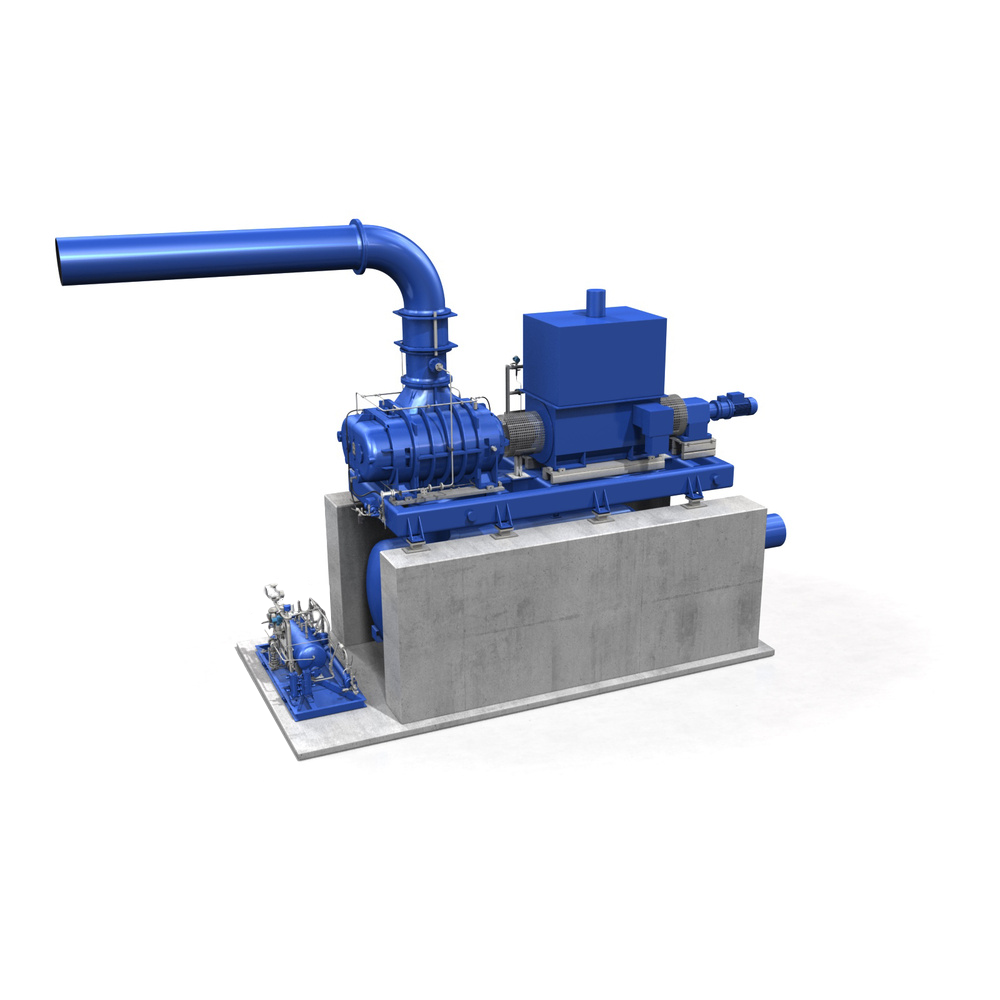

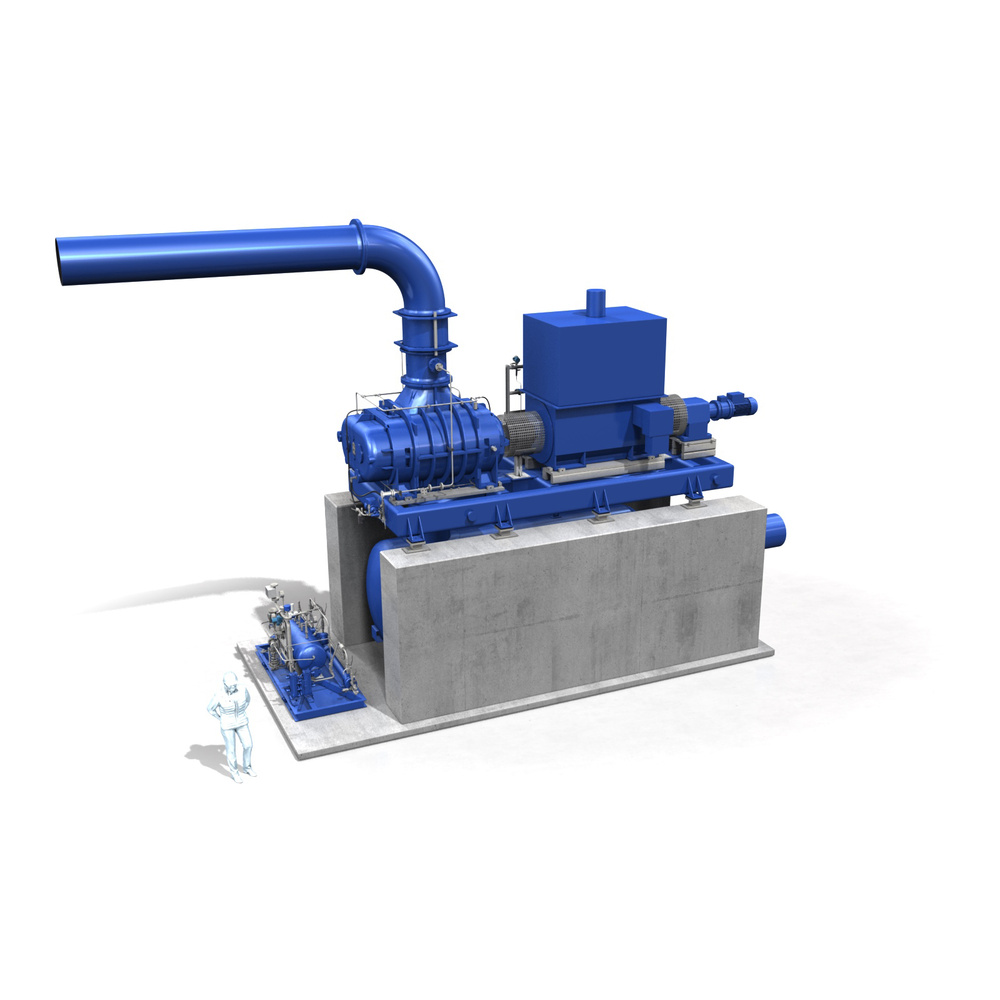

Positive Displacement Blowers

Process Gas Blower

Series GR

AERZEN offers the process gas and coolant industries an incredibly broad spectrum of blower technologies – perhaps the broadest of any manufacturer. Machines that operate as stand-alones, in machine or container combinations, onshore and offshore.

Volume flow:

90

to

38.000

m3/h

Differential pressure (Δp):

150

to

1.500

mbar

Medium:

Process Gases

Conveying:

Oil-free

The advantages of AERZEN Blower series GR at a glance:

- The 1 or 2 stage process blowers GR can be used for almost all technical gases and gas mixtures, which may also be aggressive.

- Versatile blower stage (single and two-stage) for plant engineering for vertical and oil-free conveyance.

- Direct drive, with gear box or belt drive. Optionally available with liquid injection for gas cooling or purification, as well as with special modifications and materials.

Process gas blowers from AERZEN function reliably in all industries, in all markets, and in all countries on earth.

AERZEN offers the process gas and coolant industries an incredibly broad spectrum of blower technologies – perhaps the broadest of any manufacturer. Machines that operate as stand-alones, in machine or container combinations, onshore and offshore. In every single key industrial application:

Chemical and petrochemical industries

- Compression of H2 and CH mixtures

- Acetylene

- Ethylenes

- Lime kiln gas

- Rich gas

- Synthesis raw gas

- Butadiene

- Vinyl chloride

- Hydrogen sulphide

- Hydrogen

Refineries

- Hydrocracking

- Hydrosulphurisation

- Fractionating

- Reforming

- Catalytic cracking

- PSA

- Flare gas

- Compression of H2 and CH mixtures Energy production

- Gas turbine supply

- Steam

Oil & gas conveyance and storage

- VOC recovery

- Natural gas compression

- Pipeline booster

- Underground gas storage

Industrial gases

- Hydrogen generation

- Air separation

- Argon

- Syngas Coolant industry

- Coolants (R1270, R290, etc.)

Helium refrigerator and liquefier

- Helium

Offshore

- Natural gas compression

Breweries

- Waste steam

Pharmaceuticals & coking plants

US Units

No- Type of technology

- Positive Displacement Blowers

- Differential pressure (Δp)

- 150 to 1.500 mbar

- Volume flow

- 90 to 38.000 m3/h

- Medium

- Process Gases

- Conveying

- Oil-free

Blower Power For Special Requirements

The 1- or 2-stage process blowers GR can be used variably for almost all technical gases and mixed gases. In all industrial sectors. Ideal also for gases with negative intake temperatures down to -40 °C. The process gas blower type GR can also be used to convey aggressive gases Maximum pressure increase of 1.5 bar, maximum pressure 6 bar g

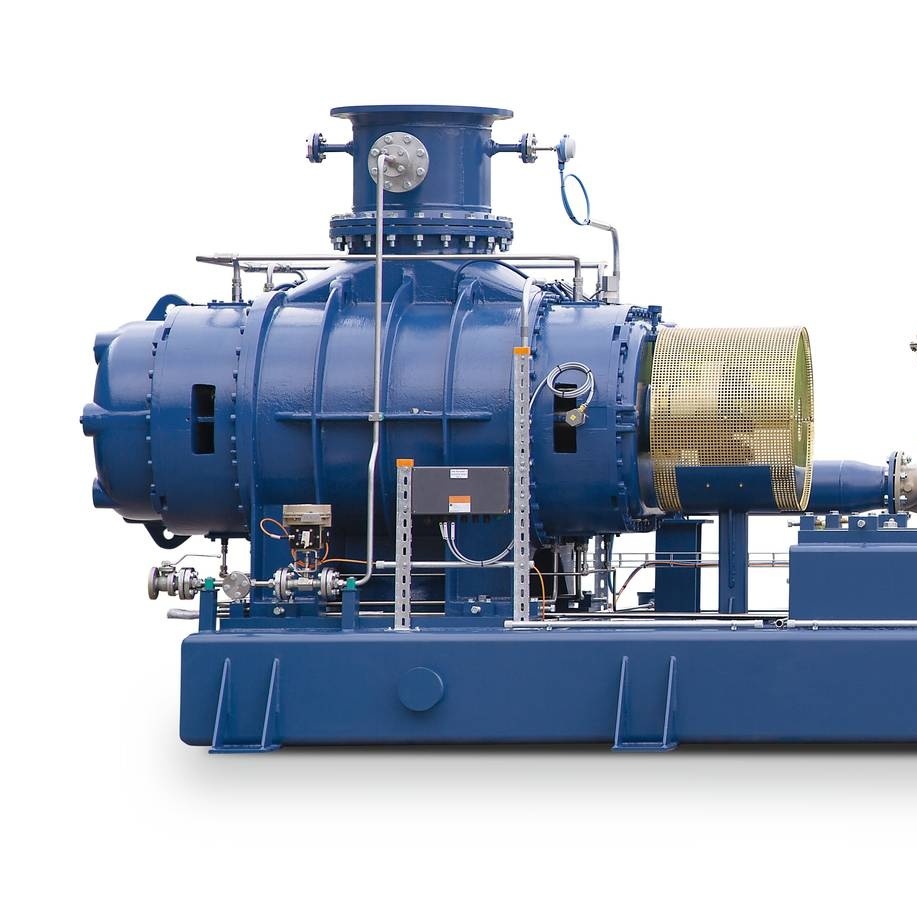

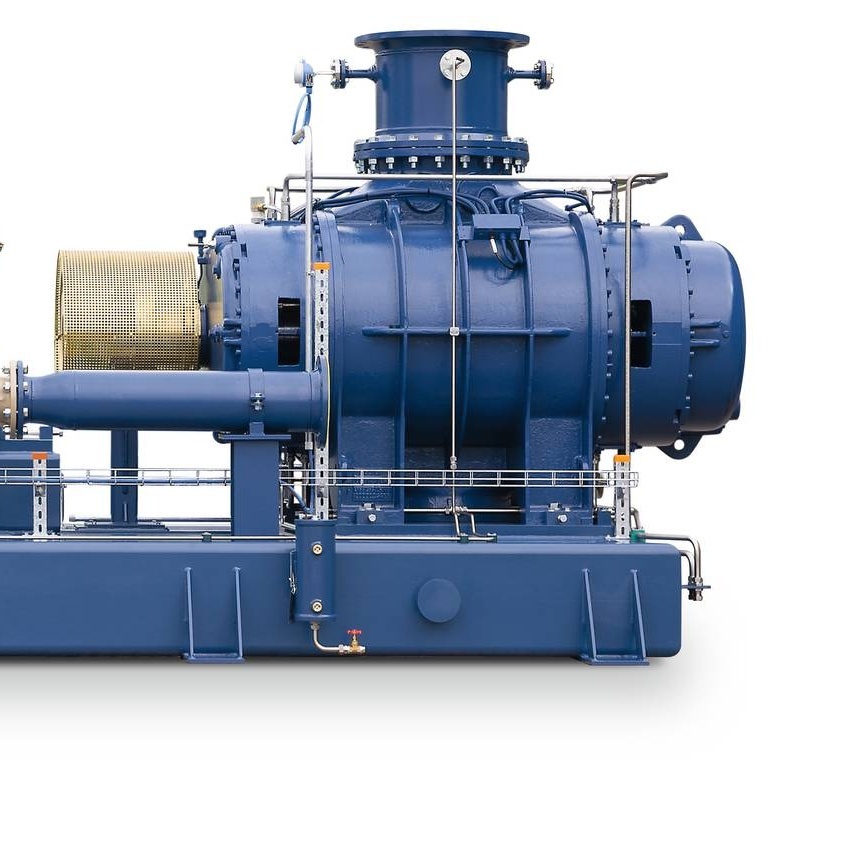

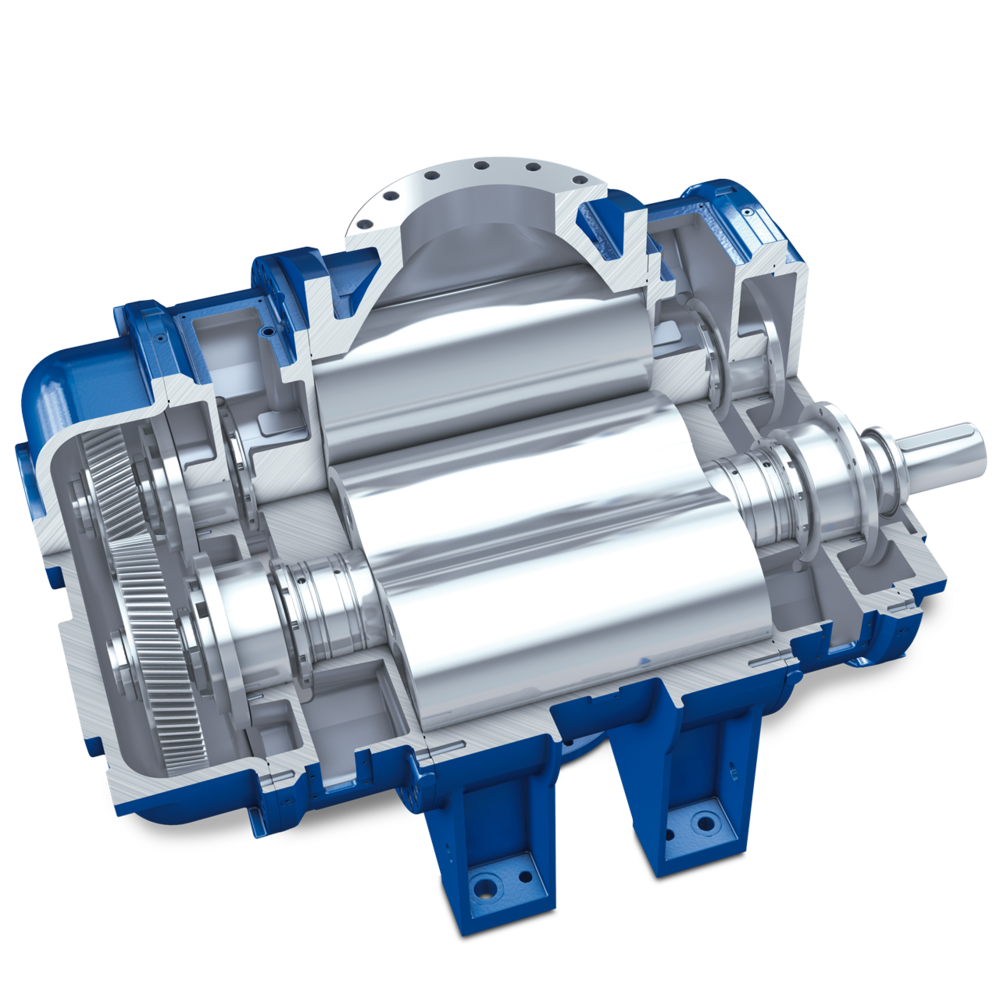

Design

The conveying chamber is completely separated from the oil sumps by a space open to atmosphere.

- Maximum pressure increase of 1.5 bar

- Maximum pressure 6 bar (g)

Shaft Seals:

Conveying chamber sealed by

- a) pressure relieved soft packings with purge gas connections,

- b) pressure relieved carbon ring - labyrinth seals with purge gas connections,

- c) double-acting mechanical seals, oil-purged,

- d) double-acting mechanical seals, water-purged.

Drive shaft by radial seal ring.

Direction og flow:

Vertically downwards.

Drive:

Direct via flexible coupling or via flexibly coupled spur gear. Overhung via narrow V-belt (up to 250 kW driving power).

Special materials: Depending on the particular operating conditions, models are also available in nodular graphite cast iron or CrNi cast steel.